1.Elevator: It is used for material lifting and conveying. The potatoes can be easily poured into the hopper manually, and the material can be continuously and evenly lifted to the next process through the conveyor belt, which saves a lot of labor and is convenient and practical.

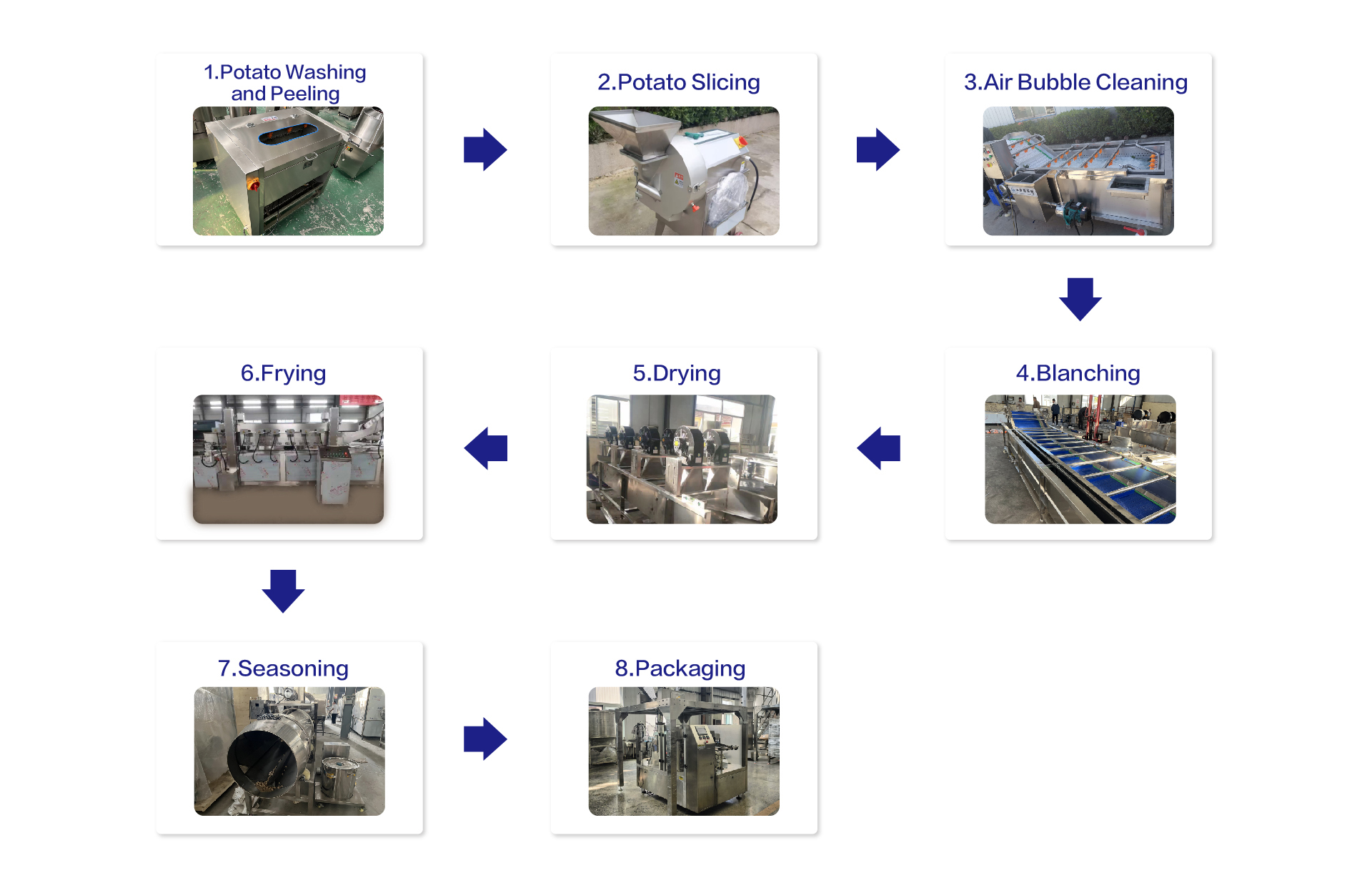

2.Cleaning and peeling machine: The potatoes that come in can be cleaned and peeled, and the materials are fed and discharged at the same time, which can work continuously.

3.Picking belt: To pick and repair the cleaned and peeled potatoes. If there are any bad ones, they need to be picked out.

4.Potato cutter machine: Put the peeled and clean potatoes into the feeding port continuously, and the French fries will be automatically cut out.

5.Rinsing machine: Wash the starch of French fries.

6.Blanching machine: Blanch and fix the color of French fries, and add food additives.

7.Cooling machine: Cool the blanched French fries to prevent sticking.

8.Air-cooled dehydrator: Dry the moisture on the surface of the blanched French fries for frying.

8.Frying machine: Fry French fries. The temperature can be automatically controlled and it can work continuously.

10.Deoiling machine: Take off the oil on the surface of fried French fries.

11.Picking belt: Blow the French fries to cool for packaging, and pick unqualified fries.

12.Seasoning machine: Season the selected French fries.

13.Packing machine: Pack French fries.

| Product Name | Model | Dimension(mm) | Power | Capacity | Material |

| Hoister | HADOF-2000 | 2000*700*1400 | 0.55 KW | 1000 KG/H | SUS 304 |

| Brush Washing Machine | HADOF-800 | 1050*830*900 | 1.5 KW | 700 KG/H | SUS 304 |

| Blanching Machine | HADOF-3000 | 2500*1100*1300 | 36 KW | 300 KG/H | SUS 304 |

| Dewatering Machine | HADOF-TY800 | 13701260*1650 | 1.65 KW | 400-600 KG/H | SUS 304 |

| Continuous Frying Machine | HADOF-4000 | 4000*1200*2400 | 100 KW | 600 KG/H | SUS 304 |

| Deoil Machine | HADOF-TY800 | 1370*1260*1650 | 1.65 KW | 400-600 KG/H | SUS 304 |

| Flavour Machine | HADOF-500 | 1100*1000*1300 | 1.5 KW | 500 KG/H | SUS 304 |

| (Reference Only) |

Rich Experience

In Export

Oversea Installation

Service

Environmentally

Friendly

High Quality

Assurance

Free Designing

Scheme

Customer Oriented

Service

×

×