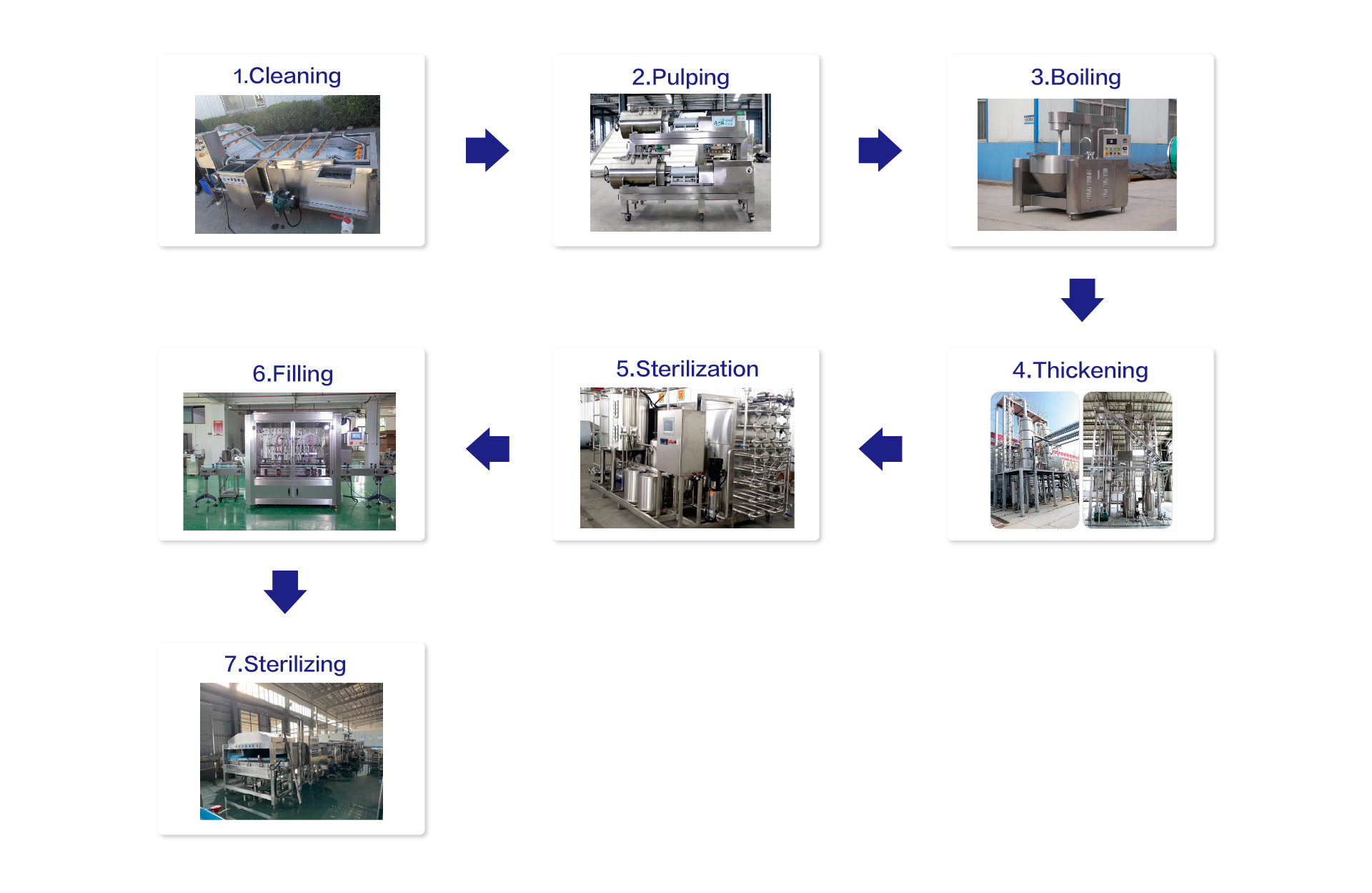

Process:

Cleaning – pulping – boiling – thickening – sterilization – filling – sterilizing

| Product Name | Dimension(mm) | Power(KW) | Material |

| bubble washing machine | 2500*1200*1300 | 2.25 | SUS304 |

| dual channel pulper | 750*480*890 | 0.75 | SUS304 |

| planetary stirring pots | 1800*1650*1750 | 4 | SUS304 |

| falling film concentrator | 3000*1000*2000 | 10 | SUS304 |

| tube steriliser | 3200*1600*2000 | 1.5 | SUS304 |

| automatic servo filling machine | 3500*1200*1600 | 3 | SUS304 |

| tunnel cooling steriliser | 5000*2000*2000 | 10 | SUS304 |

| (Reference Only) |

Rich Experience

In Export

Oversea Installation

Service

Environmentally

Friendly

High Quality

Assurance

Free Designing

Scheme

Customer Oriented

Service

×

×