1.Screening: Select tomatoes that are fresh, ripe and free of pests and diseases.

2.Washing: Wash the tomatoes to remove sediment, impurities and pesticide residues.

3.Elevating: Elevator conveying tomatoes.

4.Air-drying: Air-dry the water.

5.Crushing: Crushes the cleaned tomatoes into small pieces.

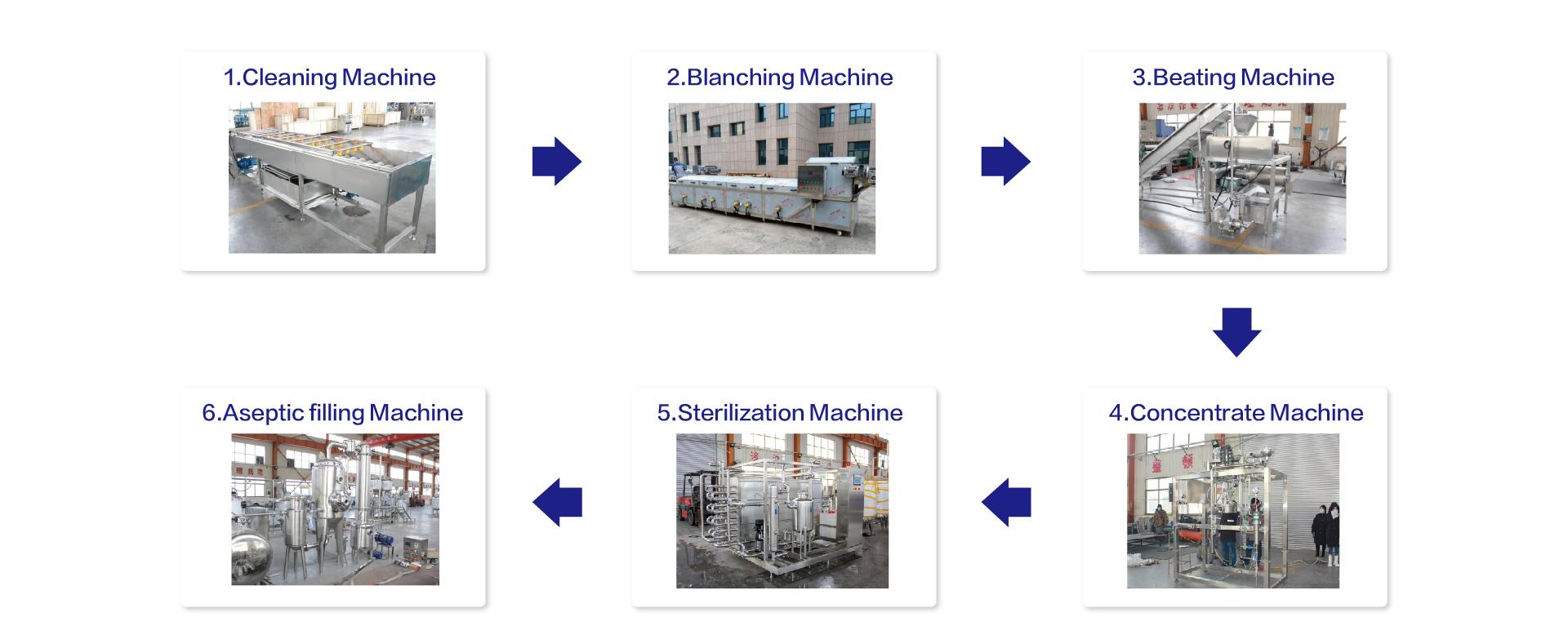

6.Pulsing: The equipment is used to separate the tomato skin from the seeds to obtain tomato pulp.

7.Concentration: The tomato pulp is heated and concentrated to remove excess water and achieve the desired consistency.

8.Sterilisation: The tomato paste is heated to a specific temperature and kept for a certain period of time to kill harmful micro-organisms and extend the shelf life.

| Product Name | Dimension | Power | Material |

| Bubble Washing Machine | 2800*850*1300 | 3KW-10KW | SUS 304 |

| Pulping Machine | 1800*1000*1600 | 5KW-30KW | SUS 304 |

| Tube Steriliser | 2000*1000*2000 | 0.5KW-15KW | SUS 304 |

| Mixing Tank | 500L – 5000L | 0.5KW-100KW | SUS 304 |

| Condenser | 3000*1500*3000 | 5KW-50KW | SUS 304 |

| (Reference Only) |

Rich Experience

In Export

Oversea Installation

Service

Environmentally

Friendly

High Quality

Assurance

Free Designing

Scheme

Customer Oriented

Service

×

×